Advanteges

Application

Plasma gouging is ideal for eliminating welding defects, cracks, cavities and inclusions and for preparing for backwelding.

Unique Technology

Side Blowing

Unique side blowing technology provide good track of gouge process,better control of gouging depth and width, which improve gouging efficiency.

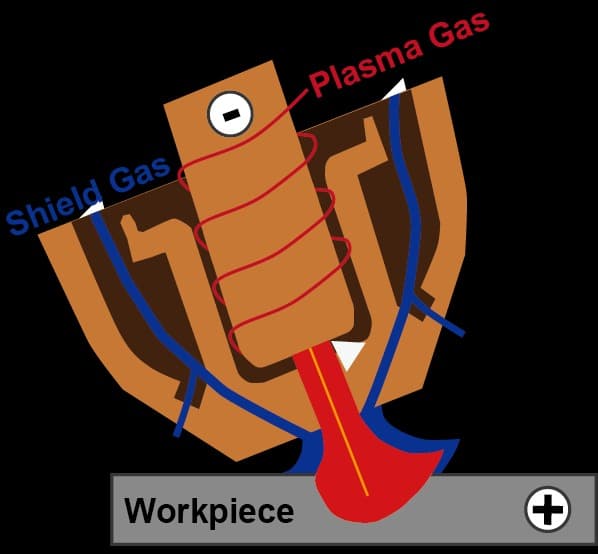

Dual Air Plasma Gouging System

Separate plasma and shielding gases to optimize the performance.

gouge profile

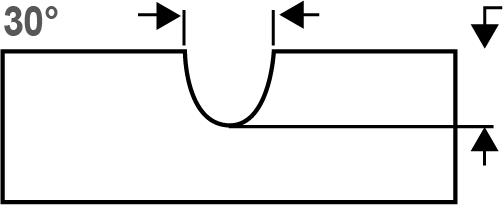

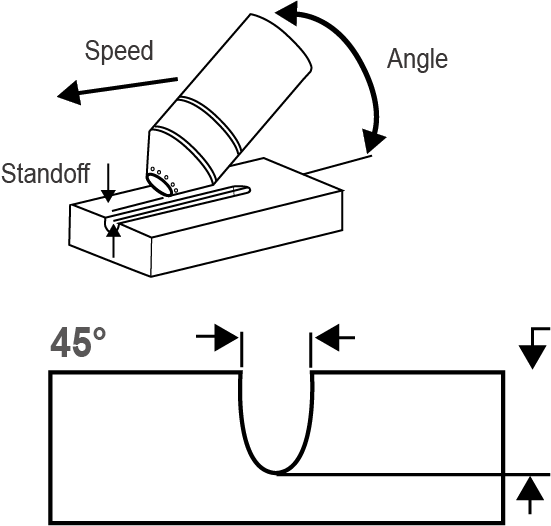

You can vary the gouge profile by varying the:

Profiles by 30° and 45° a torch angles are illustrated in follow:

Get updates on sales specials and more

We want to hear from you!

Copyright © 2022 HANGZHOU TOPWELL TECHNOLOGY CO.,LTD. | 浙ICP备2022006748号